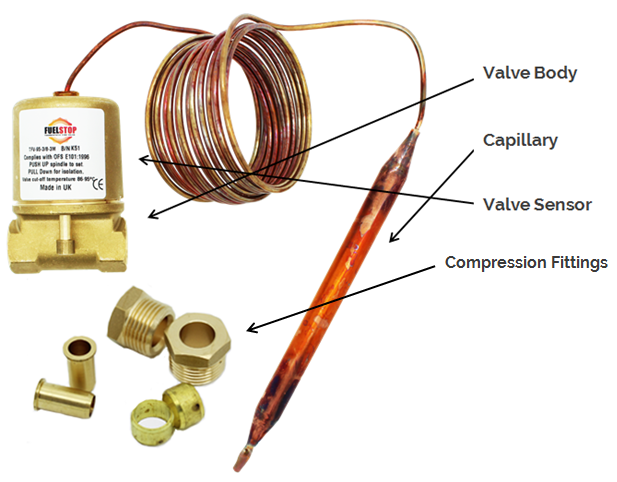

The Fuelstop ‘TFV’ was the first capillary operated fire valve to incorporate an integral shut off facility as part of the reset mechanism and is also supplied with 10mm tube nuts and olives as standard on the 3/8″ body size, allowing time saving and economical installation.

The Fuelstop ‘TFV’ was the first capillary operated fire valve to incorporate an integral shut off facility as part of the reset mechanism and is also supplied with 10mm tube nuts and olives as standard on the 3/8″ body size, allowing time saving and economical installation.

All TFV fire valves are suitable for use with Class C and D fuels as well as LPG, and provide automatic shut off in the event of an overheat within a fuel burning appliance and fail safe shut off in the event of capillary or sensor failure.

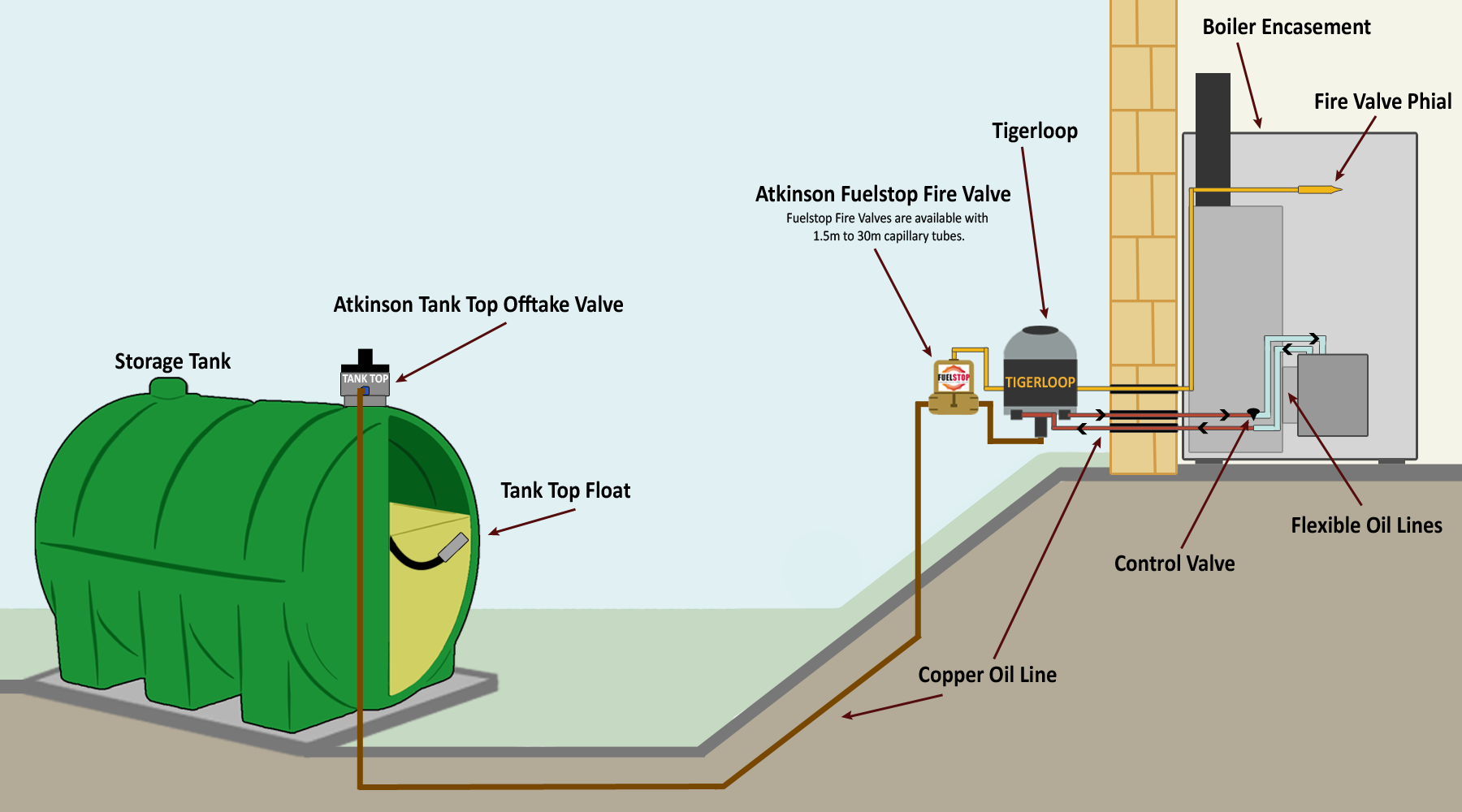

The valve body, which is installed outside the external wall of the property.

The capillary runs from the valve body to inside the property, inside the boiler housing next to the oil burner.

The valve sensor detects the expansion from the capillary and will shut off the valve.

The Fuelstop TFVs are manufactured in two temperature ranges; 66 to 72°C and 86 to 95°C for installations where higher temperatures are likely.

If the temperature in the fuel burning appliance exceeds the temperature range appropriate for that valve, the liquid inside the capillary expands and causes the valve to shut down, cutting off the supply of fuel to the appliance immediately.